The United States Occupational Safety and Health Administration (OSHA) requires employers to be prepared for eye emergencies by providing eyewash and shower equipment in an area that is no farther than 55 feet away and requires a worker no more than 10 seconds to reach.

The guidelines were outlined on the website of Occupational Health & Safety, an industry journal based in Dallas, Texas.

OSHA eye care requirements

The OSHA requirement for emergency eye care on the job reads:

“Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.”

If a chemical splash to the eyes occurs, the victim is likely to be suffering from irritation, pain and potentially blindness. The victim must be able to get to the washing equipment as easily and quickly as possible.

Eyewash units and emergency showers must be installed in well-lit areas free from obstacles. They should be installed with prominent signs so that a person with an eye injury can find it. The washing unit must be equipped to be activated in one second or less.

Be prepared for emergencies

Being prepared for emergency eye care on the job means that the eyewash units and emergency showers should be installed right beside areas where dangerous materials are being used.

If multiple employees are exposed to the chemicals, there should be enough stations so all employees have easy access.

Managers and supervisors in workplaces that feature hazardous materials are responsible for providing ways to avoid injuries like scalds and burns. So it’s important for managers and supervisors to be diligent in being prepared for emergency eye care on the job. That includes training to prepare for a quick response with eyewash and emergency shower equipment. They should also try to prevent these accidents from happening in the first place.

Eyewash stations provide a controlled flow of water to both eyes to flush away spills, splashes, dust, and debris. Generally, these stations deliver a 15-minute, uninterrupted flow of tepid water. Drains are typically installed directly below or nearby to prevent buildups of water and chemicals on the floor.

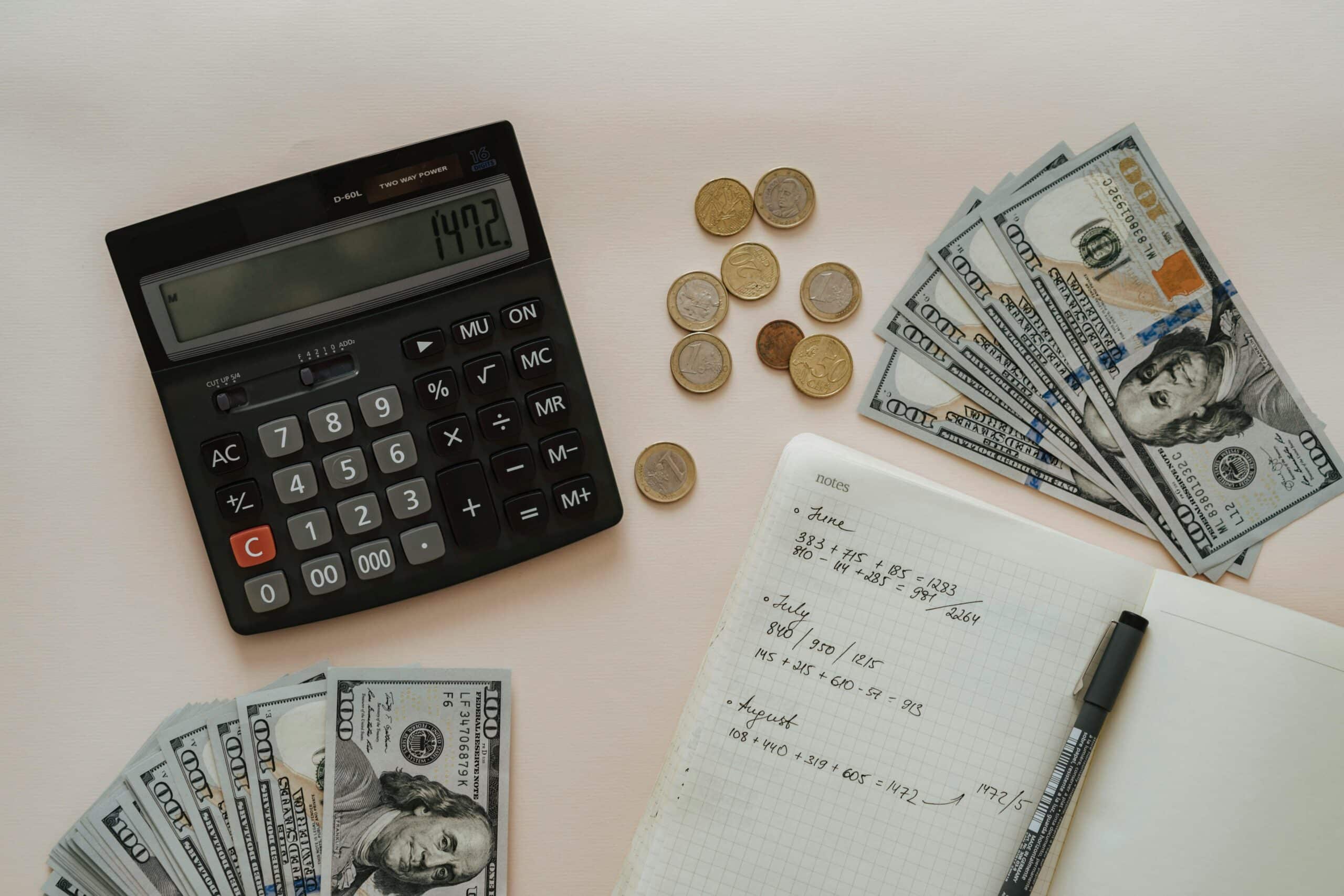

The cost of eyewash stations ranges from over $70 to over $3,500, with some equipped with a decontamination area and other features, according to Home Depot and other online vendors.

Primary types of eyewash equipment

Generally, there are three types of eyewash equipment for emergency eye care on the job:

- Plumbed eyewash units are connected to a facility’s plumbing. They’re able to supply a greater flow rate of water compared to self-contained units. They’re able to supply between two and five gallons per minute

- Self-contained/gravity fed eyewash equipment holds the eyewash solution in a chamber within the unit. The chamber can provide 15 minutes of flushing and must be refilled after use. This option is for locations where equipment can’t be connected to a facility’s plumbing.

- Personal eyewash is often supplied in single-use bottles. It used primarily on the spot and while a victim is being moved to an eyewash unit for additional treatment. Personal eyewash treatments must not be used alone and must be accompanied by exposure to a 15-minute flushing station.

Contact Kotlar Hernandez & Cohen Law Offices in New Jersey today for help with cases of eye injuries on the job, as well as for help with any other workers’ compensation issues.